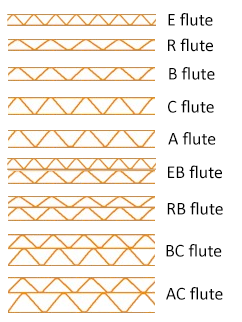

The final aspect of the corrugated board that can affect its performance (and weight and cost), is the flute type.

The flute is the “corrugated” section between the two liners, and by changing its’ height (and therefore the size of the flutes) it is possible to achieve different performance characteristics.

This can vary from very fine flutes such as “E” to manufacture lightweight retail cartons (being very good to print onto), through to a more coarse flute such as an “A” or “B” flute more usually used for transit packaging.

As in the examples above, with double walled material, it is possible to combine one or more flutes to create a grade such as an “EB” or “BC” flute. This can offer a rigid structure perfect for heavier items, whilst also allowing an improved aesthetic outer appearance and printing surface.

The flute itself is usually manufactured from a waste based fluting (WBF – i.e., fully recycled material) or what is known as semi-chem fluting (SC).

Typical paper weights used for fluting are as follows:

- 90 GSM WBF

- 105 GSM WBF – Most Common Flute Standard

- 112 SC and WBF

- 150 SC and WBF

- 175 SC and F

There are also a number of commonly used flute profiles or sizes, which are as follows:

- A FLUTE: 5mm

- B FLUTE: 3mm

- C FLUTE: 4mm

- E FLUTE: 1.5mm

- F FLUTE: 1mm

- BC FLUTE: Double Wall – 6mm -Combination of B + C flutes

- EB FLUTE: Double Wall – 4.5mm -Combination of E + B flutes

Again, this list is not exhaustive, and is complicated by the fact that many producers of corrugated material make very similar products.

So Which ones are the best for you to choose?